Detailed Product Description

Botanical Characteristics

Malt is derived from the mature seeds of barley (Hordeum vulgare), a member of the Poaceae family, after germination and drying. Barley is an annual or biennial herbaceous plant, 50-150 cm tall. The culm is erect, smooth and glabrous, with 3-5 nodes. The leaf sheath is loose around the stem, the ligule is membranous, 1-2 mm long; the leaf blade is flat, lanceolate, 15-30 cm long, 6-15 mm wide, rough on the upper surface, relatively smooth on the lower surface.

The spike is erect, 4-8 cm long (excluding awns), 1-1.5 cm wide; spikelets contain 3 florets, only the lowest one is fertile; glumes are linear, extending into 8-14 mm awns at the apex; lemma has no hairs on the back, 5-veined, with rough awns 8-13 cm long; palea is equal in length to the lemma. The caryopsis adheres to the inner and outer glumes after maturity and is not easily detached.

Growing Environment

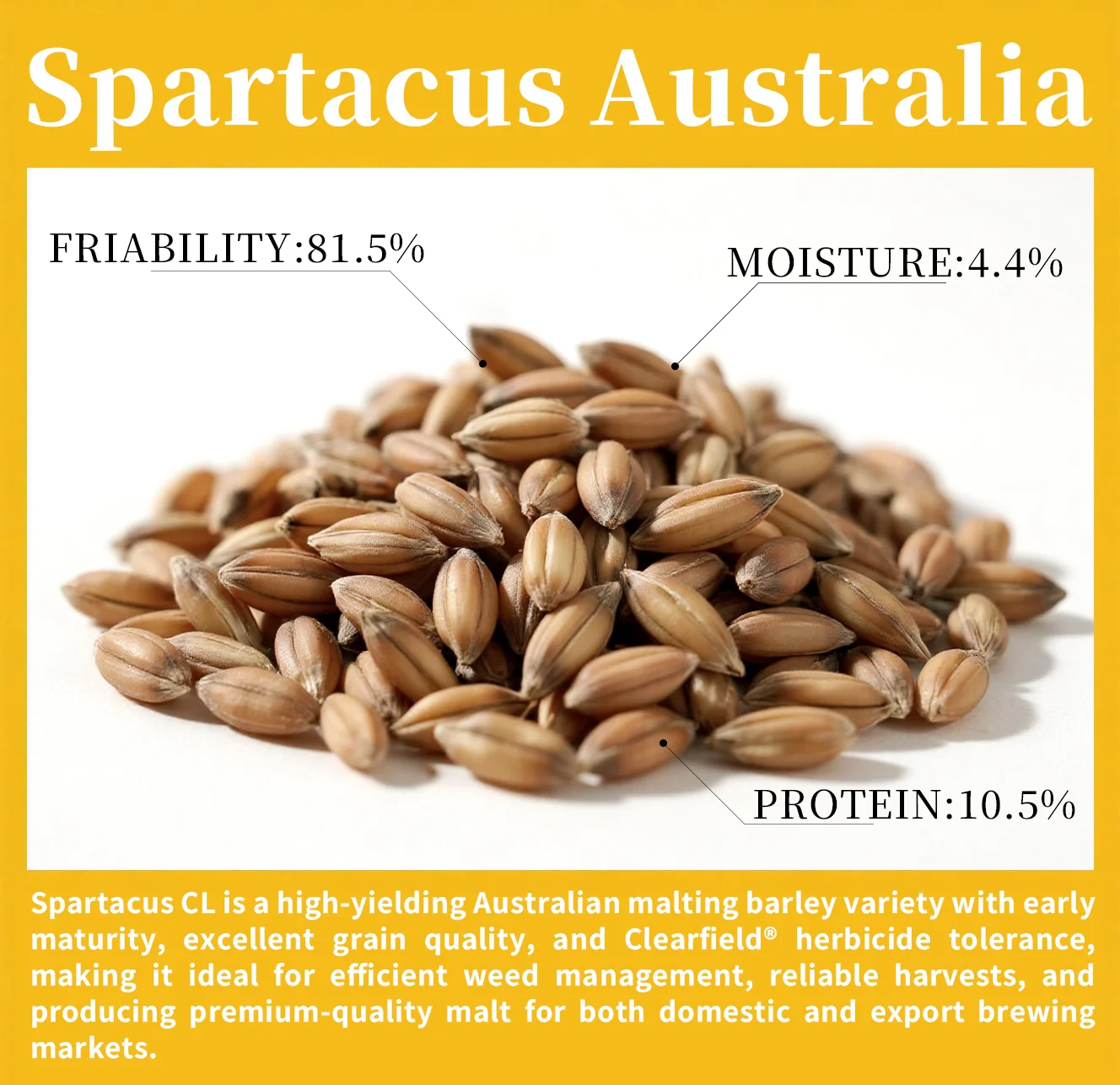

Barley, the raw material for malt, prefers cool and dry climate with strong cold resistance, suitable for growing in areas with an annual average temperature of 10-16°C. We have established high-quality raw material bases in Guangxi, Canada, Australia and other regions. These regions have suitable climate, fertile soil, and large temperature differences between day and night, which are conducive to the nutritional accumulation of barley.

Barley has strong soil adaptability, but deep, fertile, well-drained loam or sandy loam is preferred. We adopt scientific planting management techniques, select high-quality varieties, and strictly control irrigation and fertilization to ensure the quality of raw barley. During the germination process, we use advanced temperature-controlled germination systems to ensure uniform malt growth and strong enzyme activity.

Harvesting and Processing

The production cycle of malt includes planting, harvesting, storage, germination and drying of raw barley. After strict screening, the raw barley is germinated under controlled temperature and humidity conditions, usually for 5-7 days. During germination, temperature and humidity need to be strictly controlled to ensure optimal enzyme activity.

After germination is complete, the malt needs to be dried. The drying temperature is controlled in stages, first low-temperature drying to remove surface moisture, then high-temperature roasting to fix enzyme activity and color. The entire processing process strictly follows the ISO quality management system to ensure product consistency and traceability. We provide various types of malt products, including pale malt, slow roast malt, specialty malt and sour malt.

Quality Characteristics

High-quality malt is pale yellow to golden yellow grains, full and uniform, with luster, no mold, no insect damage, no odor. Malt grains are complete, uniform in size, germination rate above 95%, strong enzyme activity, high saccharification power. Moisture content is controlled within 5%, and the screening system has a removal rate above 98%.

Our malt products are provided by Guangxi Tianxiang Guose Trading Co., Ltd., using high-quality two-row barley from Canada and Australia as raw materials, processed through advanced germination and drying processes. The products cover various types such as pale malt, slow roast malt, specialty malt and sour malt, suitable for brewing needs of different beer styles. The products strictly follow the ISO quality management system to ensure stable and reliable quality.